Introduction

In this post we’ll explain the different types of plastic manufactured and in what products they are transformed. You may be thinking, “Isn’t plastic all the same?”. Plastic isn’t as simple as you may think, in fact, there are hundreds of types of plastic (also called polymers), but only a handful that we interact with on a regular basis. Some are reusable, others produce hazardous material after several uses, some are easily recyclable, others need more sophisticated and intricate handlings in its recycling process. Take your nearest plastic product, a lunch box, sanitiser or bottle of water. You should find a number on the bottom. This number indicates the type of plastic used to make the product.

Why is knowing what the difference plastic types is important?

Having knowledge of the different types of plastic is critical to understanding the complexity of recycling, upcycling and the health factors associated with plastic.

Do you know exactly what number you should avoid and what number holds the biggest chance of damaging the environment? Not all plastic is bad. Humanity has certainly benefited from it in some ways and you can even make arguments that support that it’s also been beneficial to the environment – although in very specific examples.

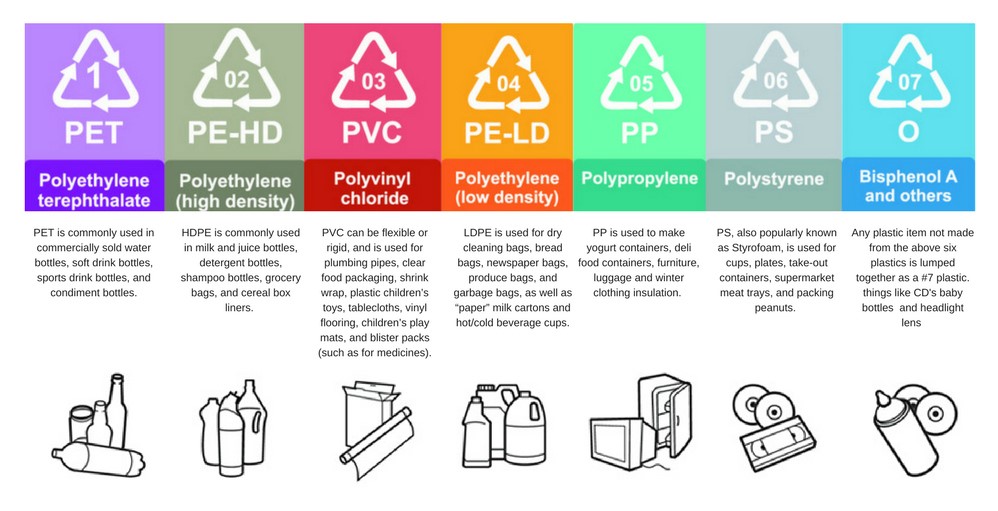

There are several types of plastic used currently:

Plastic is often a more efficient material to choose than alternatives. That’s because plastics are incredibly energy efficient to manufacture and because they are lighter than alternative materials. 900g of plastic can deliver 37.8L of a beverage. You’d need 1.3kg of aluminum, 3.6kg of steel, or over 18kg of glass to bring home the same amount of a beverage. Here’s a look at some plastic resins and some of the ways they’re commonly used in packaging applications.

Regulatory agencies that monitor food and beverage production require the use of food-grade materials at any point that the material may contact food. Packaging is no exception to these rules, leading to the development of food-safe plastics for use in packaging consumable products. Food-grade plastics follow stringent, government-monitored manufacturing processes to ensure they are safe for food contact. Numerous plastics are approved for food contact, leading to their use as food packaging.

1. Polyethylene Terephthalate (PET, PETE, Polester)

PET is clear, tough, and has good gas and moisture barrier properties. It is also known as a wrinkle-free fiber. It is relatively universal; used in soft drink and single-use water bottles, as well as food-grade containers, bakery trays, snack packs, produce containers and other injection-moulded consumer product containers. It also helps to keep the carbon dioxide in carbonated drinks from getting out and its strong ability to prevent oxygen from getting in and spoiling the product inside. PET resin won’t degrade upon food contact, which makes it a popular choice for food packaging. Some of the other beneficial properties of PET include lightweight, high impact resistance, and corrosion resistance.

Cleaned, recycled PET flakes and pellets are in great demand for spinning fiber for carpet yarns and producing fiberfill and geotextiles.

Although PET is most likely to be picked up by recycling programs, this type of plastic contains antimony trioxide—a matter that is considered as a carcinogen—capable of causing cancer in a living tissue. The longer a liquid is left in a PET container the greater the potential for the release of the antimony. Warm temperatures inside cars, garages, and enclosed storage could also increase the release of the hazardous matter.

Properties:

- Clear and optically smooth surfaces for oriented films and bottles

- Excellent barrier to oxygen, water, and carbon dioxide

- High impact capability and shatter resistance

- Excellent resistance to most solvents

- Capability

Common Packaging Applications:

- Plastic bottles for soft drinks, water, juice, sports drinks, beer, mouthwash, and salad dressing

- Food jars for peanut butter, jam and pickles

- Polyester clothing or rope

- Oven friendly film and microwavable food trays

# Crystallizable Polyethylene Terephthalate (CPET)

CPET has undergone a process to make it more resistant to cracking when it experiences impacts at low temperatures, which is a common drawback of some standard PET plastic containers. CPET is more flexible and can withstand higher temperatures, making it appropriate for producing plastic food trays used with conventional oven, microwavable dinners, oven-proof plastic wrap, microwaveable storage containers, and more. CPET is also commonly used for ready-to-eat meals as well.

2. High-Density Polyethylene (HDPE)

HDPE is the most widely used type of plastic. It’s used to make many types of bottles and containers. Unpigmented bottles are translucent, have good barrier properties and stiffness, and are well suited to packaging products with a short shelf life such as milk. Because HDPE has good chemical resistance, it is used for packaging many household and industrial chemicals such as detergents and bleach. Pigmented HDPE bottles have better stress crack resistance than unpigmented HDPE. Quite special compared to the other types, HDPE has long virtually unbranched polymer chains which makes them really dense and thus, stronger and thicker than PET.

Not only recyclable, HDPE is relatively more stable than PET. It is considered as a safer option for food and drinks use, although some studies have shown that it can leach estrogen-mimicking additive chemicals that could disrupt human’s hormonal system when exposed to ultraviolet light.

Properties:

- Higher tensile strength compared to other forms of polyethylene

- Excellent resistance to most solvents

- Relatively stiff material with useful temperature capabilities

Common Packaging Applications:

- Bottles for milk, water, juice, cosmetics, shampoo, dish and laundry detergents, medicine bottles and household cleaners

- Bags for groceries and retail purchases

- Cereal box liners

- Toys, buckets

- Park benches and rigid pipes

3. Polyvinyl Chloride (PVC, Vinyl)

In addition to its stable physical properties, PVC has good chemical resistance, weatherability, flow characteristics, and stable electrical properties. The diverse slate of vinyl products can be broadly divided into rigid and flexible materials.

This hard and rigid plastic is desired for building and construction applications; while the fact that it doesn’t conduct electricity makes it common for high-tech applications, such as wires and cable.

It’s also widely used in medical applications because it’s impermeable to germs, is easily disinfected and provides single-use applications that reduce infections in healthcare.

PVC is typically used in toys, blister wrap, cling wrap, detergent bottles, loose-leaf binders, blood bags and medical tubing.

PVC or vinyl used to be the second most widely used plastic resin in the world (after polyethylene), before the manufacture and disposal process of PVC has been declared as the cause of serious health risks and environmental pollution issues.

In the term of toxicity, PVC is considered as the most hazardous plastic. The use of it may leach a variety of toxic chemicals such as bisphenol A (BPA), phthalates, lead, dioxins, mercury, and cadmium.

Several of the chemicals mentioned may cause cancer; it could also cause allergic symptoms in children and disrupt the human’s hormonal system. PVS is also rarely accepted by recycling programs. This is why PVC is better best to be avoided at all cost.

Properties:

- Brilliant clarity

- High impact strength

- Excellent processing performance

- Resistance to grease, oil, and chemicals

Common Packaging Applications:

- Rigid packaging applications include:

- Blister packs and clamshells

- Plumbing pipes, credit cards, human and pet toys, rain gutters, teething rings, IV fluid bags and medical tubing, oxygen masks

- Flexible packaging uses include:

- Bags for bedding and medical, shrink wrap, deli and meet wrap and tamper resistance

4. Low Density Polyethylene (LDPE)

Includes Linear Low-Density Polyethylene (LLDPE)

LDPE is used predominately in film applications due to its toughness, flexibility, and relative transparency, making it popular for use in applications where heat sealing is necessary. LDPE also is used to manufacture some flexible lids and bottles as well as in wire and cable applications.

This type of plastic has the simplest plastic polymer chemical structure, making it very easy and very cheap to process. LDPE polymers have significant chain branching including long side chains making it less dense and less crystalline (structurally ordered) and thus a generally thinner more flexible form of polyethylene.

Although some studies have shown that LDPE could also cause unhealthy hormonal effects in humans, LDPE is considered as a safer plastic option for food and drink use. Unfortunately, this type of plastic is quite difficult to be recycled.

Properties:

- A softer, clearer, and more flexible version of HDPE

- Excellent resistance to acids, bases, and vegetable oils

- Toughness, flexibility, and relative transparency; good combination of properties for packaging applications requiring heat-sealing

Common Packaging Applications:

- Bags for dry cleaning, newspapers, bread, frozen foods, fresh produce, and household garbage

- Shrink wrap and stretch film, bubble wrap

- Coatings for paper milk cartons and hot and cold beverage cups

- food storage containers and Container lids

- Squeezable bottles (e.g., honey and mustard)

- Also used for wire and cable covering.

5. Polypropylene (PP)

Same as LDPE, PP is considered a safer plastic option for food and drink use. Polypropylene is an ideal food-safe plastic for production processes that require high heat. PP has good chemical resistance, is strong, and has a high melting point making it good for hot-fill liquids.

This is one of the most durable types of plastic. It is more heat resistant than some others. It’s flexible enough to allow for mild bending, but it retains its shape and strength for a long time. Its strength quality is somewhere between LDPE and HDPE. While fairly stiff, polypropylene is not as brittle as other common food packaging plastics.

It can be found in products ranging from prescription bottles to garden tools and automotive products.

And although it bears all these amazing qualities, PP isn’t quite recyclable and could also cause asthma and hormone disruption in human.

Properties:

- Excellent optical clarity in biaxially oriented films and stretch blow moulded containers

- Low moisture vapor transmission

- Inertness toward acids, alkalis, and most solvents

Common Packaging Applications:

- Containers for yogurt, margarine, takeout / ready-to-eat meals, and deli foods (hot food), VSP containers

- Medicine bottles

- Bottle caps and closures

- Bottles for catsup and syrup

- Straws

- Packaging tape

- Disposable diapers and sanitary pad liners.

- Thermal vests, car parts

6. Polystyrene (PS or Styrofoam)

Polystyrene (PS) is the styrofoam we all commonly use for food containers, disposable cups and bowls, and protective packaging.

PS is a versatile plastic that can be rigid or foamed. This rigid plastic is low-cost and insulates very well, which has made it a staple in the food, packaging and construction industries.

General purpose polystyrene is clear, hard, and brittle. It has a relatively low melting point. PS is often combined with rubber to make high impact polystyrene (HIPS) which is used for packaging and durable applications requiring toughness, but not clarity.

When exposed with hot and oily food, PS could leach styrene that is considered as brain and nervous system toxicant. It could also affect genes, lungs, liver, and immune system. On top of all of those risks, PS has a low recycling rate. Like PVC, polystyrene is considered to be a dangerous plastic

Properties:

- Excellent moisture barrier for short shelf life products Excellent optical clarity in general purpose form

- Significant stiffness in both foamed and rigid forms

- Low density and high stiffness in foamed applications

- Low thermal conductivity and excellent insulation properties in foamed form

Common Packaging Applications:

- Food service items, such as cups, plates, bowls, cutlery, hinged takeout containers (clamshells), meat and poultry trays, and rigid food containers (e.g., yogurt)

- These items may be made with foamed or non-foamed PS.

- Shipping and product packaging

- Building insulation.

7. Other

Number 7 is for all plastics other than those identified by number 1-6 and also plastics that may be layered or mixed with other types of plastics, such as bioplastics. The most important thing here is that these plastics aren’t typically recyclable.

Examples: Eyeglasses, baby and sports bottles, electronics, CD/DVDs, lighting fixtures and clear plastic cutlery.

Polycarbonate (PC) is the most common plastic in this category, isn’t used as much in recent years due to it being associated with bisphenol A (BPA). PC is also known by various name: Lexan, Makrolon, and Makroclear.

Ironically, PC is typically used for baby bottles, sippy cups, water bottles, water gallon, metal food can liner, sauce containers, and dental sealants. Due to its toxicity, several countries have banned the use of PC for baby bottles and infant formula packaging.

The BPA that contained inside PC have been linked to numerous health problems including chromosome damage in female ovaries, decreased sperm production in males, early onset of puberty, and various behavioural changes.

It has also been linked to altered immune function, sex reversal in frogs, impaired brain and neurological functions, cardiovascular system damage, adult-onset (Type II) diabetes, obesity, resistance to chemotherapy, increased risk of breast cancer, prostate cancer, infertility, and metabolic disorders.

Added with its very low recycle rate quality, PC is to be avoided at all cost.

In Closing

Memorizing all of those 7 different types of plastic could be overwhelming, so here are several key points you need to remember:

- Though it varies between types, every single category of plastic could leach hazardous materials if put in an extreme situation such as extreme heat.

- Three types of plastic that are considered as safer options among the others are Polyethylene Terephthalate (PET), High-Density Polyethylene (2-HDPE), and Polypropylene (5-PP).

- Although the experts are currently working on inventing the best method and strategy to recycle all of those types of plastic, the 2 types of plastic that are mostly picked up by the recycling programs are Polyethylene Terephthalate (1-PET) and High-Density Polyethylene (2-HDPE).

Plastic is a complex material, just as its production, distribution and consumption are. We encourage you to dive in deeper in order to understand all these complexities, such as plastic properties, recyclability, health hazards and alternatives, including the pros and cons of bioplastics.

At Waxpak, as a plastic packaging manufacturer, we develop food grade packaging solutions mainly in rPET, Polypropylene and High impact polystyrene- all our materials contain at least 50% post-consumer recycled waste and at least 30% industry recycled waste. More recently we have been able to offer 100% rPET solutions! All Our thermoform films are manufactured in-house using the latest extrusion machinery and technology.

Everything we manufacture is 100% recyclable and we welcome drop off’s at our facility in Chamdor, Krugersdorp. With a reputation for stringent quality to exacting standards, we hold A BRC Global Standard for Packaging and Packaging Materials.

[mailpoet_form id=”1″]

“Resins and Types of Packaging” Plastic Packaging Facts,https://www.plasticpackagingfacts.org/plastic-packaging/resins-types-of-packaging/

Bahraini, Amanda. “7 Types of Plastic that You Need to Know” waste4change, 17 July 2018, https://waste4change.com/blog/7-types-plastic-need-know/

Firn, Clare.“Types of Plastic Food Packaging” Point Five, 16 October 2020, https://www.p5pkg.com/blog/types-of-plastic-food-packaging/